Brine and Metal Wastes Valorisation to Produce Coagulants for Wastewater Treatment

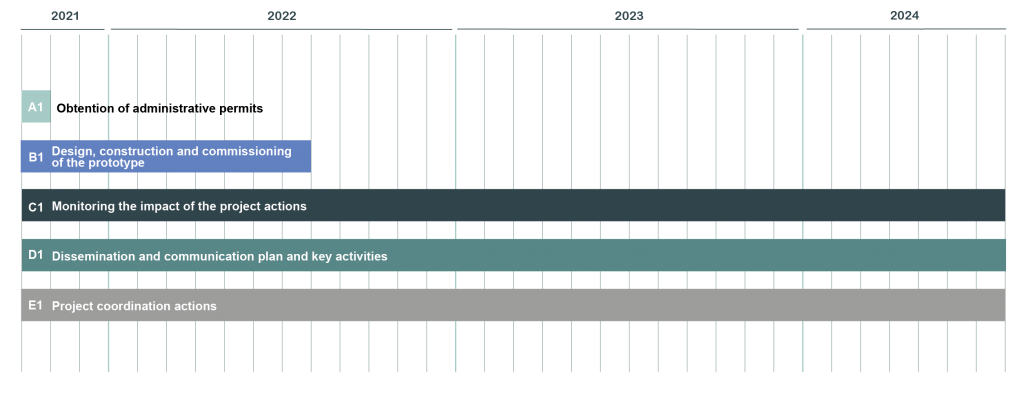

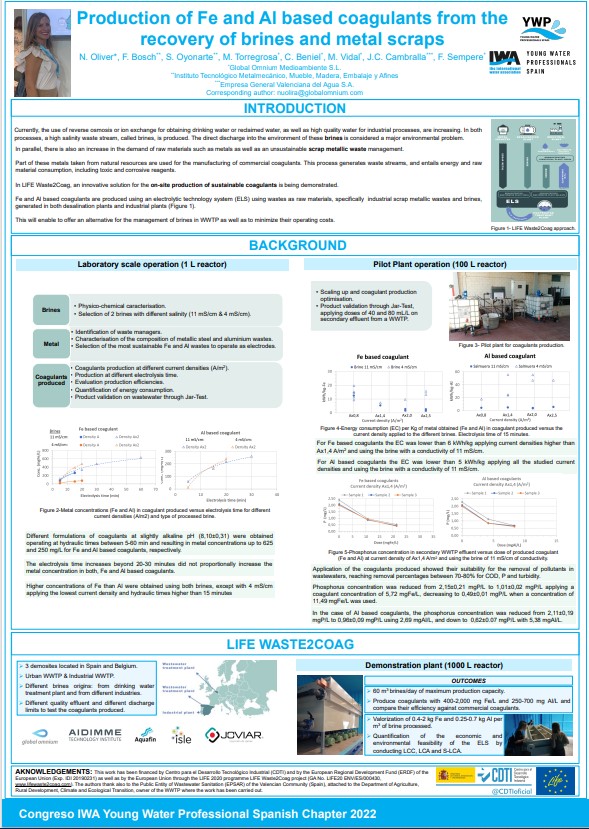

LIFE Waste2Coag aims to demonstrate an innovative and cost-efficient technology based on the electrolysis of wastes to produce coagulants for the removal of pollutants in urban and industrial wastewaters, including emerging pollutants and pathogens.

LIFE Waste2Coag boosts the circular economy in water treatment plants and creates synergies with other sectors, as industrial scrap metallic wastes and brines generated in different industries are valorised, including wastewater treatment plants (WWTP) and desalination plants (DP).

Expected Results

Design, build and operate an electrolytic pilot plant, using wastes as secondary raw materials to produce coagulants with an estimated maximum capacity of around 60m³ /day

Valorisation of 75m³/week in Gandia WWTP (100% of received brines), 400 m³/week in Wulpen WWTP, 1.5m³ /week in JOVIAR industrial plant (100% of generated brines in their process). A total of 5000m³ during project duration

Adjustable metal concentration in the produced coagulants of 400-2,000 mgFe/L and 250-700 mgAl/L

Partners

Latest News

-

LIFE Waste2Coag is revolutionising the wastewater treatment process

The LIFE Waste2Coag project co-funded by the EU LIFE programme (LIFE20 ENV/ES/000430) has recently entered its 3rd year and is making great strides in its transformation of the wastewater treatment process.

-

We held our first LIFE Waste2Coag webinar

Recently our project partner Isle Utilities hosted the first LIFE Waste2Coag webinar! The webinar was held online on the 11th July 2023 and reached a variety of industry professionals looking to understand the ongoing work and research involved in the LIFE Waste2Coag project.

-

LIFE Waste2Coag Poster Presentations

Two posters explaining the work done by the partners within the LIFE Waste2Coag project are available for download in the resources page.