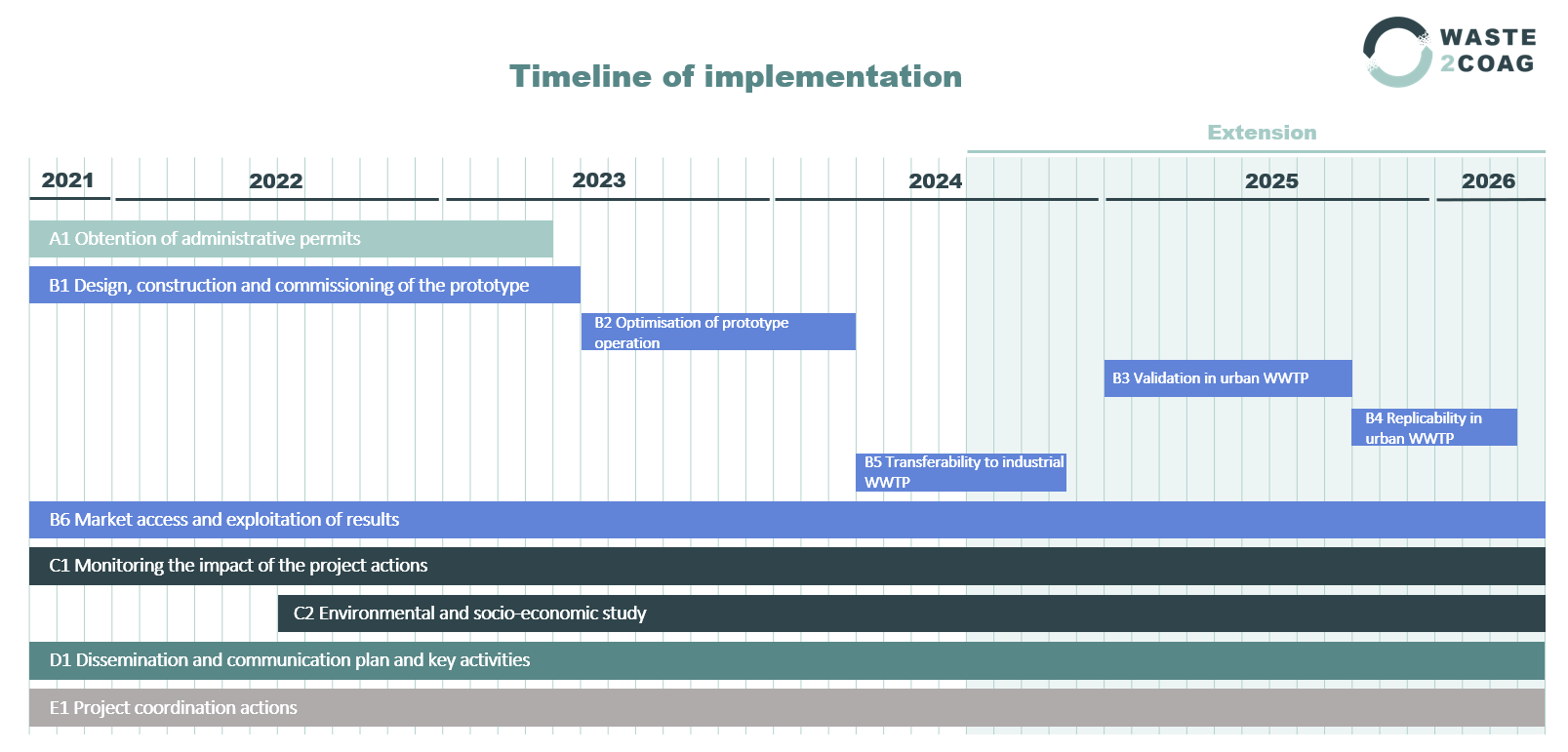

Actions

Timeline for LIFE Waste2Coag

This action deals with obtaining the required permits to carry out the project in the three different demosites, one urban WWTP in Spain and another one in Belgium, and one industrial plant in Spain.

The ELS prototype will be designed, based on scrap metals instead of commercial electrodes to valorise brines into Fe and Al coagulants that will be dosed to treat wastewater in industrial and urban WWTPs. The size of the ELS reactor module is already industrial, avoiding further scaling-up of the system to smooth the path to market uptake

The ELS prototype will be operated in the urban WWTP in Spain, which currently receives 50-75 m3/week of brines of different origin, normally from 7 industrial suppliers and that are discharged to the WWTP without any valorisation. Brines will be physico-chemically characterised to ensure their adequateness to be processed in the ELS prototype to produce coagulants, which will be evaluated for wastewater treatment as alternative to commercial products. The operational parameters and procedures will be optimised to achieve the best conditions in terms of energy consumption and product quality. Brine characterisation will enable to set operational parameters mapping of ELS based on each type of brine. Jar-test experiments of the coagulants will be carried out to compare their efficiency with commercial products to ensure adequate product application.

The efficiency of the Fe and Al metal-based coagulants produced by the ELS prototype will be demonstrated and validated after the optimisation phase (action B2). This will enable the improvement of the WWTP effluent quality before its discharge to the Mediterranean sea and/or to make it susceptible as environmental flow in the final stretch of the river where it could be discharged.

The ELS prototype will be transported from the urban WWTP in Spain to the urban WWTP in Belgium, where it will be run following the protocols carried out in actions B2 and B3. The Belgian WWTP is located right next to a drinking water facility with a continuous production of brine from RO treatment, which currently is not valorised in a sustainable way. The operational protocols and mappings for the valorisation of part of these brines into coagulants will be adjusted based on the brine characteristics to be processed. The product application will also be defined on the wastewater characteristics to be treated with the aim to achieve a 100% replacement of the commercial coagulants currently used in this WWTP.

The ELS prototype will be installed at an industrial plant in Spain, where it will be operated with the know-how obtained in actions B2. This industrial activity requires high quality water obtained by demineralisation systems, which generates brines intermittently from regeneration backwashing. Currently these brines are accumulated as concentrates and fed to the industrial WWTP for their treatment without any valorisation. The recovery of part of these brines into coagulants will be obtained adjusting operational parameters of the ELS according to the characteristics of the brines to be processed. The application of the coagulant produced will also be defined according to the characteristics of the wastewater to be treated with the aim of replacing the commercial lime slurry currently used as coagulant by Fe or Al salts in situ produced. If the results of the validation task regarding coagulant substitution are positive, the consortium commits to treat 100% of this industrial plant’s wastewater during the After-LIFE period.

The Exploitation and business strategy plan (EBSP) of the project results is a crucial tool for helping the project to reach its exploitation and business goals, define strategies and actions that will be required to achieve them and be competitive within the market. The ESBP will maximise market reach and impact of the LIFE Waste2Coag solution, protect the innovations generated and develop activities to promote replicability and transferability of results. As part of the EBSP, a business model based on the industrial symbiosis concept will be created. A replicability and transferability strategy will be developed in this action to boost replication by encouraging the adoption, implementation and further replication of the project results, proposing them as best available technology for EU Best Available Techniques reference document (BREF). A Best Practices & Replicability and Transferability guideline document will be produced. This guide will be a tool that will be used for future replicability and transferability of the Waste2Coag solution.

The performance indicators of the LIFE Waste2Coag project will be defined and monitored. The monitoring of the degree of the compliance of the different indicators in each action will be carried out and merged to be fully analysed within this action, giving an overall and detailed impact of the project implementation. The monitoring will be conducted throughout the project period and until three years after the end of the project as part of the After-LIFE Plan.

The quantification and evaluation of the economic, environmental and social impacts of the implementation of LIFE Waste2Coag solution to produce Fe and Al coagulants from metal scraps and brines to improve the quality of urban and industrial WWTP, through Life Cycle Sustainability Analysis (LCSA).

This action aims at promoting and disseminating the project results at regional, national and international level to the relevant stakeholders and audiences. The dissemination of project results will be one of the most important actions of the project and will be carried out during and After-LIFE project execution.

As part of this action, a Dissemination and Communication plan (D&CP) of the project will be prepared. The D&CP will outline the targeted audience, key messages and communications channels. The D&CP will support action B6 identifying actions to make the Waste2Coag project results available to the targeted audience including key stakeholders and identifying barriers and risks to market uptake and strategies to overcome them. The most relevant events to disseminate the project results will be identified, and key actors engaged to support the project results to ensure a long-lasting impact of the project after LIFE. Networking with other European and global projects will be encouraged through their involvement in relevant activities to maximise dissemination of the results, knowledge transfer and sharing lessons learnt.

The formation of a strong structure to achieve effective and result-driven management, ensuring objectives are clearly defined and visible throughout the project. To set up active administrative and technical management, monitoring progress among planned and actual activities, identifying risks and issuing corrective action plans as necessary, ensuring efficient financial management and delivery of reports to the EC. To set the basis for the After-LIFE exploitation of the project results.